AL811H Amplifier Myths, Changes, and Information

[ Home ]

Business Page Link

CTR Engineering, Inc

Also see:

AL811, AL811H,

AL572, other amps trouble shooting guide

811A Tube History

and Construction

Power Gain of AL811H Amplifier

The older AL811H (prior to drive resistor modification) with good

tubes and stable power line, when properly tuned and operating in the linear

region, has about 11 dB gain. This is an amplification of about twelve

times. With 60 watts of drive power, output is 720 watts. The power gain

is slightly higher on SSB than on carrier or high average power modes, but the

gain will be

reasonably close on

all bands. The largest single problem with significantly greater or less gain

(power output) is a poorly calibrated power meter. A mismatched antenna or load

can falsely increase power readings.

| Note: If you tune the amplifier at reduced drive power, gain increases. |

The following is typical measured gain of an early (pre-2011)

unmodified with good tubes

at 7 MHz with carrier power. Gain is slightly higher on SSB or low duty cycle,

because anode voltage is slightly higher. Units containing the shunt 200-ohm resistor require about 20% more

drive. HV is 1500 volts at full load:

| Drive watts

old style |

Drive watts

new style |

Power Output watts |

| 20 | 27 | 250 |

| 35 | 42 | 440 |

| 50 | 60 | 615 |

| 65 | 75 | 715 |

| 75 | 90 | 750 |

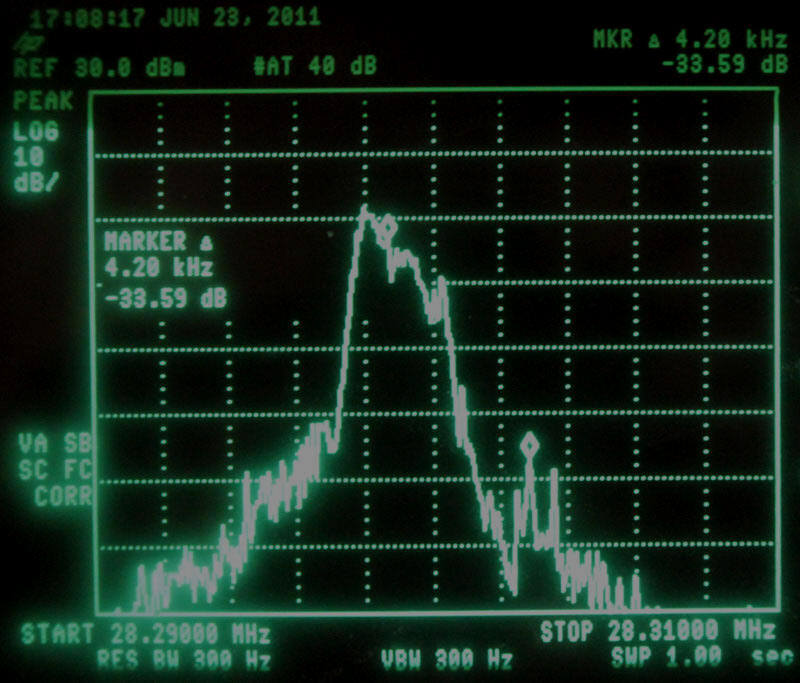

AL811H, highest peak power, in sidebands with normal voice

modulation at 700 watts PEP with fresh tubes on worse band, ten meters.

Next channel up, strongest peak is about -34 dB compared

directly to voice channel median power level.

LSB is about -32 dB, not much different than the barefoot

transmitter.

Properly tuned with good tubes, the AL811H adds

negligible bandwidth to a typical radio’s SSB signal, even on the worse-case

band.

This performance can be improved with a TOF

module.

Some AL-811 Myths on Internet

There is some history of the 811A tube at

this link.

A few common but false myths are:

811 tubes are critical for grid current

Factually, the largest number of field failures are damage to

anodes from excessive anode heating and low filament emission from poor tube

manufacturing quality. Grid related failures

are nearly non-existent. The most common cause of operational or customer

induced tube failure is excessive anode

dissipation over time. Heat is a function of duty cycle and short term average

dissipation. The 30-second or longer time-period dissipation (dissipation

is not the same as output power) must be kept below 60 watts. For short

periods (IVS service) dissipation can be much higher.

Life of 811 tubes will be extended by less anode voltage

Anode voltage, within reasonable limits, has nothing to do with

tube life or tube arcing. Virtually no tube failures relate to anode voltage.

Life of 811 tubes are extended by more airflow

811 tubes are designed to be natural convection cooled. Anodes,

which produce most of the heat, and the other heat sources are inside a sealed

glass envelope in a vacuum. There is very little heat conduction to the

envelope. The vast majority of heat is removed via infrared radiation and

radiated to tube surroundings. The only thing the air does is cool the glass

enough to prevent damage to seals or the glass envelope itself. External airflow

does not measurably improve anode cooling, and anode temperature is the limiting

parameter. See his link…airflow temperature

measurements

The 811H pushes tubes far beyond ratings

Absolutely true, if you consider operation in ICAS

or CCS and not IVS (intermittent voice service). Keep in mind however the 811H does not “push”

the tubes any “harder” than Collins did in the 30L1, or Heath did in the

Warrior. It has been a long standing tradition to run 811 tubes at about 250

watts dc plate input, which is about 150-175 watts RF on the anode, per tube.

This is why the Collins 30L1 was marketed as a “kilowatt” amplifier,

which is

over 600 watts output carrier.

The problem is not exceeding the 65-watt

dissipation for short periods, the problem is exceeding it with enough duty

cycle to overheat the anode. The most common problem today by far, excluding operator error,

is quality and design of tubes. Please read about

how the 811 tube got better, and then worse, with design evolutions.

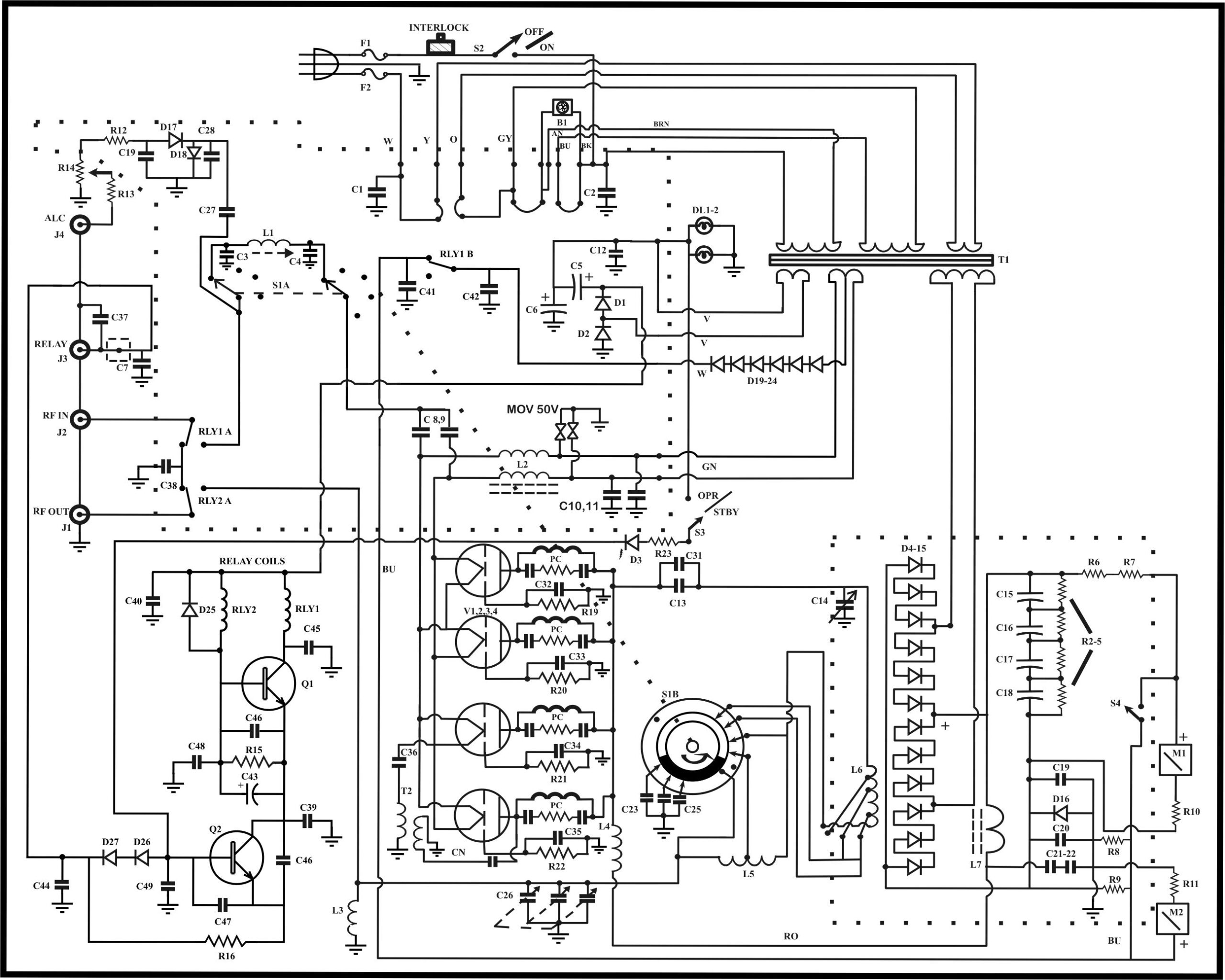

Below, hand drawn schematic early AL811H

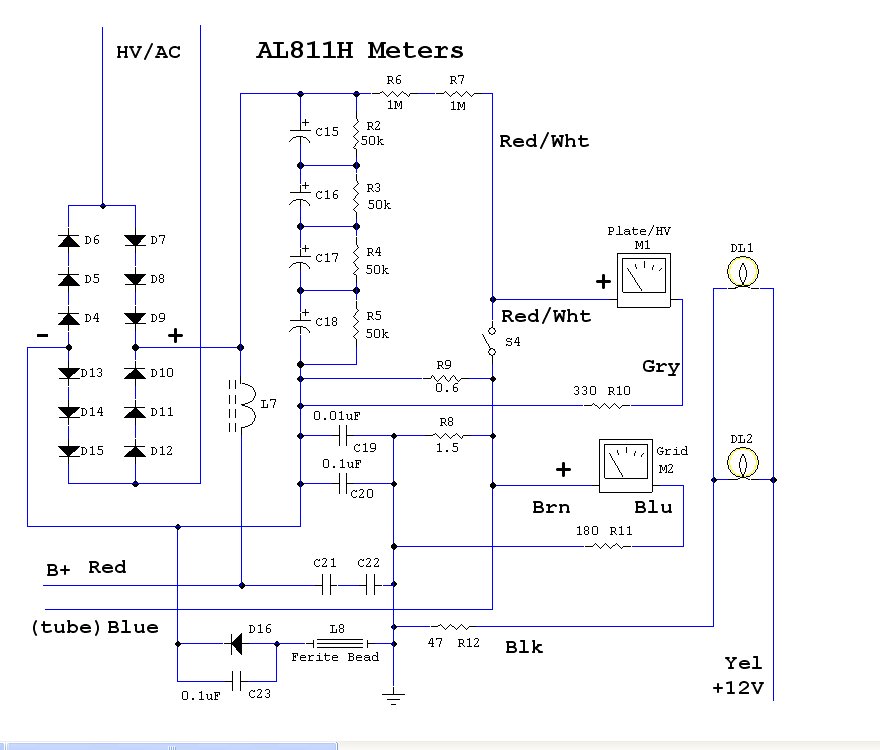

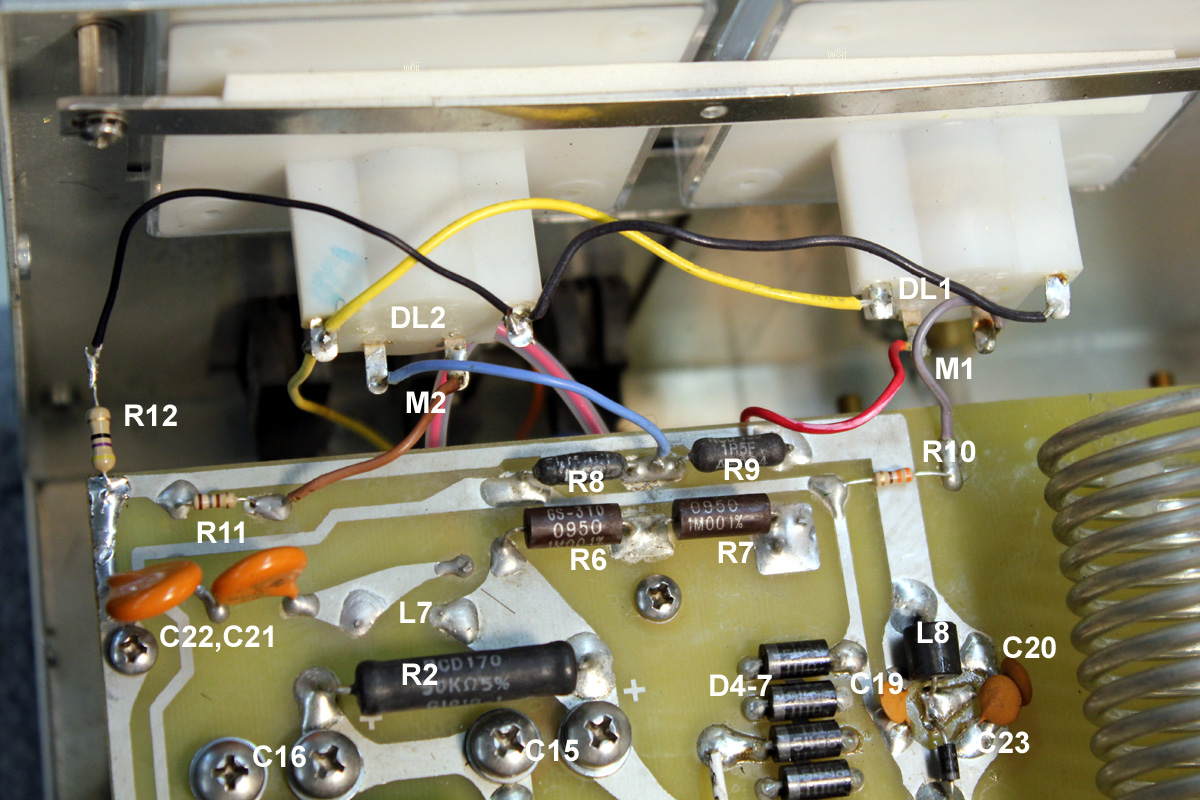

New metering schematic:

Meter protection diode D16 is the unlabeled small black diode

near C23. It protects the meters in the event of an arc. If D16 fails from an

arc, the grid and plate current meters will track. The grid meter will no longer

read grid current and the plate current meter will no longer read plate current.

They each will read a combination of plate and grid currents. This diode can be

replaced with any 1 to 5 amp silicon power rectifier diode that physically fits.

Design History

I designed the AL811 series amplifiers in the late 1980’s or early 1990’s. The

original concept by marketing was a cheap, two-tube amplifier, but I convinced

marketing that the life of two tubes would be far too short. I talked them into

a bare bones minimum three tube amp, and a slightly more refined four-tube amp.

Amazingly, the 811H has become the largest selling amplifier in the world! This

is largely due to the limited budget of most Hams, and the large power increase

per dollar investment.

I was also involved in several Heathkit designs, including a Warrior II that

fell fate to Heathkit’s exit from the amateur market. I still have a few

original prototypes of the Heathkit amplifiers.

Similar Amps

The Heathkit Warrior, Gonset 811 amp, and Collins 30L1 are all amps using four

811A tubes. All of these amps, like the AL811H, push the 811 tubes pretty hard.

They are all rated at a kilowatt dc plate input on CW, as is the AL811H. This is

about 600 watts carrier or PEP CW output power.

Of the above amplifiers, the Collins 30L1 is actually the

least stable design. Heathkit, Gonset, and Ameritron were wise enough to add

neutralization but Collins did not. The result is that the Collins 30L1 was

plagued with a series of stability mods throughout production, and even the

final production units are not unconditionally stable.

The three tube AL811, like the Collins 30L1, is not neutralized.

Because the AL811 uses three tubes and directly grounds the grids, the AL811

(with only three tubes and directly grounded grids) has

less feedback capacitance than the Collins and is not as unstable as the 30L1. The AL811H,

with neutralization and other necessary additions, is a much more stable and

repeatable design.

Tube Rating

Nearly ALL tube failures are related to excessive dissipation

by improper tuning or operating, or by simple tube manufacturing defects. I have

actually seen brand new 811 tubes with fingerprints inside the envelope! Tube

quality control is nothing like it was, but at least the tubes are inexpensive.

The 811A tube has a rated dissipation of 65 watts.

Please read the link to understand the complexity of dissipation ratings for

various modes. 65-watts is the ICAS (intermittent commercial and amateur service)

811A tube rating. Because

anode dissipation limits are greatly exceeded in normal IVS (intermittent voice

service) and CW operation, as they

historically have been in every amateur

amplifier, the operator has to be very careful with tuning and duty cycle. While a few people are critical of the AL811 operation,

every 811 amplifier throughout history has pushed 811’s a similar amount. Ameritron

actually pushes the 811 tube no more than Collins or Heathkit did, both of whom

allowed 1000 watts dc input on CW. I recommend a TOF

circuit to help monitor proper operation. This circuit gives a visual

warning of excessive grid current or improper tuning. It eliminates the need to

check grid current with a steady carrier, and gives a running warning of tuning

and drive conditions that cause splatter.

Amateur use is generally not commercial service, and this is why everyone from

Collins to Gonset to Heath, and even ARRL Handbook articles, have pushed 811 tubes. The reasons the tubes

can be pushed are low tube cost and,

even when pushed, IMD (splatter or distortion) performance stays well within

acceptable limits. The 811A tube is the transmitting tube equivalent of the

“sweep tube” commonly used in the 60’s. It is just a bit more rugged and

significantly cleaner than a sweep tube.

On voice emission tests, using peak power taken over long

periods of swept peak storage, peak sideband voice IMD is around -34 dB for

third-order products with 200 watts PEP output per tube.

If you can’t quite get the hang of tuning, or you want to

“hammer” the 811 amplifier amplifier with long average-power modes or use a lot

of processing on voice, tubes will

be the weak point. It is perfectly acceptable to replace the 811 tubes with

three or four 572B tubes in the AL811 or AL811H respectively to increase duty

cycle and tube reliability. While you should

NOT run more output, duty cycle can be greatly increased without hurting

tube life.

Common Failures

The single largest problem

with the AL811 amps

is tubes. Most tube failures, as mentioned above, are caused by poor tube

manufacturing and operators who don’t quite tune fast enough or well enough, or

operators who use high duty cycle modes. The 811 tube needs short

tuning periods with at least equal time, or longer, to cool between carrier

periods. Remember it is the plate dissipation averaged over time

periods of 15 seconds or longer that cause tube heating failure problems.

- The most frequent problem

with new tubes are

tube factory failures to pump

tubes down, so they

are gassy. - The most frequent failure

mode of properly manufactured tubes

is over dissipation

and resulting heat damage to the

anode. This generally shows as a silver looking color at the center of the

anode.

When the tubes arc, the arc path is from anode to grid. If the grid resistor

opens, the grid no longer provides a grounded barrier that shields the filament

from anode voltage. This can allow the filament to pull to a high voltage of

1000 volts or more.

In the

90’s, Ameritron

added MOV’s from the

filament wires to

ground near the

filament choke

bypasses. This helped protect the exciter and parts inside the AL811.

These MOV’s, along

with R19-R22, RL1B,

and D16 sometimes

fail.

My suggestion is the grid circuit be reworked to eliminate R19-22 and directly

ground the grids with the shortest possible leads, and that gas clamp tubes of

about 150 volts or slightly less be added.

Link to AL811 mod.

This mod is also similar to the AL572 mods at

this page.

If

the grid and plate

meter track and show

similar deflection,

D16 is often the

cause. D16 is the metering protection diode, and it fails from tube arcs.

If

the amplifier shows

anode current

without being keyed

but meters are

normal, RL1B has

welded.

If the amplifier shows anode current without being keyed but

the grid meter reads backwards, the most likely cause is a tube shorted from

filament to grid.

If the amplifier operates normally but shows some bounding or

changing plate current in all operating configurations, it is possible and

common that S4 (HV/IP switch) has dirty contacts.

S4 can be cleaned by disconnecting the cables and

CAREFULLY lay the amp on its rear panel (face up) on a thick cushion. Use WD40

carefully applied through a spray tube. Carefully and slowly flood the switch

from the front panel side with a little WD40 while clicking the switch back and

forth many times. This will wet the contact paste inside the switch and wipe the

contacts clean.