Derale Fan Water Pump Controller

My new turbo system uses a sideways mounted

air-water-air intercooler system. I wanted a straight low-restriction air flow

path to the throttle body, so the intercooler sits on a platform just above the

water pump. I decided to eliminate the belt driven pump and fan in favor of an

electric pump and electric fan. I needed some way to control the electric water

pump and electric fan.

To minimize wear and tear on pumps and electric motors

and to minimize alternator load, I wanted to run my car’s water pump only as

fast as necessary. To prevent hot spots in the engine block or heads the water

has to circulate slowly during warm up. Mechanical pump cars normally use a

thermostat bypass hose to allow cold circulation. With an electric pump, I

decided to run the pump very slow during warm up and go full speed when the

engine reached desired operating temperature. This is the best way to do things

when not using a mechanical pump, thermostat, and bypass hose system.

An electric pump generally should not be run dead-headed into

a restriction. Running dead headed will increase motor current significantly.

This heats the motor and needlessly strains the vehicle’s electrical system.

Heat can damage the pump, the higher current wears down brushes faster. Using a

pulse width modulated controller will allow water to circulate slowly during

warm up and evenly warm the engine while also reducing battery load to just a

few amps. As the engine warms the PWM controller will step up motor speed,

running the motor just fast enough to maintain proper operating temperatures.

I bought several sample PWM controllers. I measured pulse

rate, peak current, average current, and electrical system noise. Some PWM

controllers were not even PWM!! Of all the controllers I tested in summer of

2015, this Derale

controller was best.

Derale PWM Controller 16795

The Derale PWM controller had a

few things I needed to work around:

1.) The Derale PWM cannot accept an existing external sensor

on regular sensor ports, like an existing gauge sensor

The reason for this is the sensor port is sourced from

5 volts through a 12k resistance, and the sensor has pulses during

controlled duty cycle operation. It works OK as it is on the supplied

Derale thermistor. This makes the sensor a little more susceptible to

external electrical noise, and prevents using external voltage as a

control. This is not an issue in their intended use, but I would not

have done a controller that way. I’m eventually going to build my own

universal PWM controller, but for now I’m using the Derale

2.) The PWM mode is relatively narrow in voltage or resistance

range. With relatively narrow external resistance changes the output will move

from off, through pulse mode, into full-on operation.

3.) The Override Circuit has great utility for my special

water pump application. The AC override can let someone set the idle speed of a

motor

Measured Data

The data below was measured on a sample Derale controller:

| resistance | Sens Voltage | Sens uA | Temp | Start ramp mA | Voltage | Ramp ∆% | Sens R KΩ | Drive duty % |

| 60000 | 4.17 | 69.4 | 100 | |||||

| 49000 | 4.02 | 82.0 | 110 | 0.171 | NA | 0.0 | 15.6 | 3 |

| 40000 | 3.85 | 96.2 | 120 | 0.195 | NA | 12.3 | 13.7 | 50 |

| 32863 | 3.66 | 111.5 | 130 | 0.215 | NA | 20.5 | 12.9 | 99 |

| 27000 | 3.46 | 128.2 | 140 | |||||

| 23238 | 3.30 | 141.9 | 150 | |||||

| 20000 | 3.13 | 156.3 | 160 | |||||

| 18404 | 3.03 | 164.5 | 165 | |||||

| 16436 | 2.89 | 175.8 | 170 | |||||

| 14794 | 2.76 | 186.6 | 175 | |||||

| 13316 | 2.63 | 197.5 | 180 | |||||

| 12048 | 2.50 | 207.9 | 185 | |||||

| 10901 | 2.38 | 218.3 | 190 | |||||

| 9893 | 2.26 | 228.4 | 195 | |||||

| 8979 | 2.14 | 238.3 | 200 | |||||

| 8161 | 2.02 | 248.0 | 205 | |||||

| 7417 | 1.91 | 257.5 | 210 | |||||

| 5000 | 1.47 | 294.1 | ||||||

| 4000 | 1.25 | 312.5 | ||||||

| 3000 | 1.00 | 333.3 | ||||||

| 2000 | 0.71 | 357.1 | ||||||

| 1000 | 0.38 | 384.6 | ||||||

| 0 | 0.00 | 416.7 | ||||||

| Override port | factory V | Sen R | F | half step | ||||

| Voltage | Off | On | % | 3.16 | 20609 | 160 | 18404.48 | |

| 9 | 28 | 1 | 3.4 | 2.89 | 16436 | 170 | 14794.24 | |

| 10 | 28 | 2 | 6.7 | 2.63 | 13316 | 180 | 12048.22 | |

| 11 | 28 | 9 | 24.3 | 2.38 | 10901 | 190 | 9893.34 | |

| 12 | 28 | 18 | 39.1 | 2.14 | 8979 | 200 | 8160.985 | |

| 13 | 34 | 28 | 45.2 | 1.91 | 7417 | 210 | ||

| 14 | 26 | 28 | 51.9 | |||||

| 15 | 7 | 28 | 80.0 | |||||

| Override port independent of supply voltage | ||||||||

| Derale Fan Controller | ©w8ji 2015 | |||||||

Reducing Derale Temperature Range

The radiator OUTLET WATER temperature has to be some amount below desired

engine temperature, or engine temperature will not be stable. The exact amount

the outlet water is below the desired temperature varies with water flow rate

and how many BTU the engine sheds at any instant of time. The exact temperature

is found quickly through experiment. If the engine temp stabilizes 20F above the

water outlet thermostat setting, the radiator fan control temperature should be

reduced by the overage temperature amount.

My application used a water pump speed controller set to 160F. After a hard

pass with the fan Derale controller set at 160F, my engine would be at 180F.

This was 20F over the desired temperature. My application required Derale

activation at 180(run)-160(t-stat) = 20F over temp. 160F(radiator outlet

fan) – 20F (engine overage) = 140F

To handle hard passes, my system needed the radiator outlet to be somewhere

around 140F. Since the Derale would not go below around 150F, I paralleled a

resistor across the Derale sensor. My application required a 33K resistor. A 33K

resistor in parallel with the sensor made the Derale controller behave as below.

Setting the Derale at 2.77V sets the water outlet tank at approximately 140F.

The exact temperature should be verified with a thermometer :

| Sens Voltage | Temp |

| 3.20 | 100 |

| 3.11 | 110 |

| 3.01 | 120 |

| 2.89 | 130 |

| 2.77 | 140 |

| 2.66 | 150 |

| 2.55 | 160 |

| 2.48 | 165 |

| 2.39 | 170 |

| 2.30 | 175 |

| 2.21 | 180 |

| 2.12 | 185 |

| 2.03 | 190 |

| 1.94 | 195 |

| 1.85 | 200 |

| 1.76 | 205 |

| 1.68 | 210 |

Override Circuit

The override circuit was marketed as a 60% speed feature, such

as running a fan when an A/C system is turned on. This implies the override is a

steady 60% rate, which it is not.

The override circuit actually changes pulse width in a very

linear fashion with voltage. This allows the override to be used as a very

useful feature.

If we add a 5k to 10k ohm adjustable control in series with

battery voltage and the override terminal, or better still add an external

regulated voltage supply, the Derale controller will have a fully adjustable

minimum speed! This is an excellent feature for water pumps or other controls.

Pump motor speed can be tailored for normal warm up without a bypass or

thermostat, and with a little additional electronics, the pump can be forced to

~80% speed or higher under wide open throttle.

Using the override port does not remove the thermal sensor

control. The override port just sets a controlled minimum speed.

Sensor Characteristics

For use with external sensors:

Note: The sensor leads carry high frequency waveforms related to switching

times. The leads cannot be bypassed, must be ground isolated, and should be kept

away from noise sources or noise sensitive systems.

Ford Sensor

Just for reference.. the Ford ECT sensor data is:

The Ford ECT transfer function is:

The Derale controller is not easily adaptable to the

Ford (or any other) sensor. Derale provides the following sensor (left side

below compared to hose barb fitting):

I made a sensor adaptor out of a hose barb fitting. This

took minimal time and worked perfectly.

Derale intends for their sensor to be screwed onto a brass probe that pokes

though the radiator fins at or near the radiator outlet. That is a good location

for running the radiator fan, but I wanted to have a controller on my water

pump. The water pump has to run slow during warm-up, and come up to full speed

when the engine water is hot. I needed to control the water pump from water

temperature at the exit point by the thermostat housing.

Many sensors are improperly designed. The thermistor

should be thermally connected to whatever is being measured, NOT to the threads

or the housing. Connecting the temperature sensing element to the housing can

cause a problem. The housing becomes part of the thermal

measurement circuit, rather than just the probe tip that physically contacts the

air or water stream we are trying to measure. A poor sensor design causes

the sensor to partly read manifold temperature and partly read water

temperature.

My goal was to have proper sensor operation while finding a way to use

the original Derale thermistor assembly. I decided to make an adaptor (adapter) from a standard

brass hose

barb that fit my manifold port, a short piece of brass or copper rod, and a chunk of Teflon rod

to seal and thermally isolate the probe from housing.

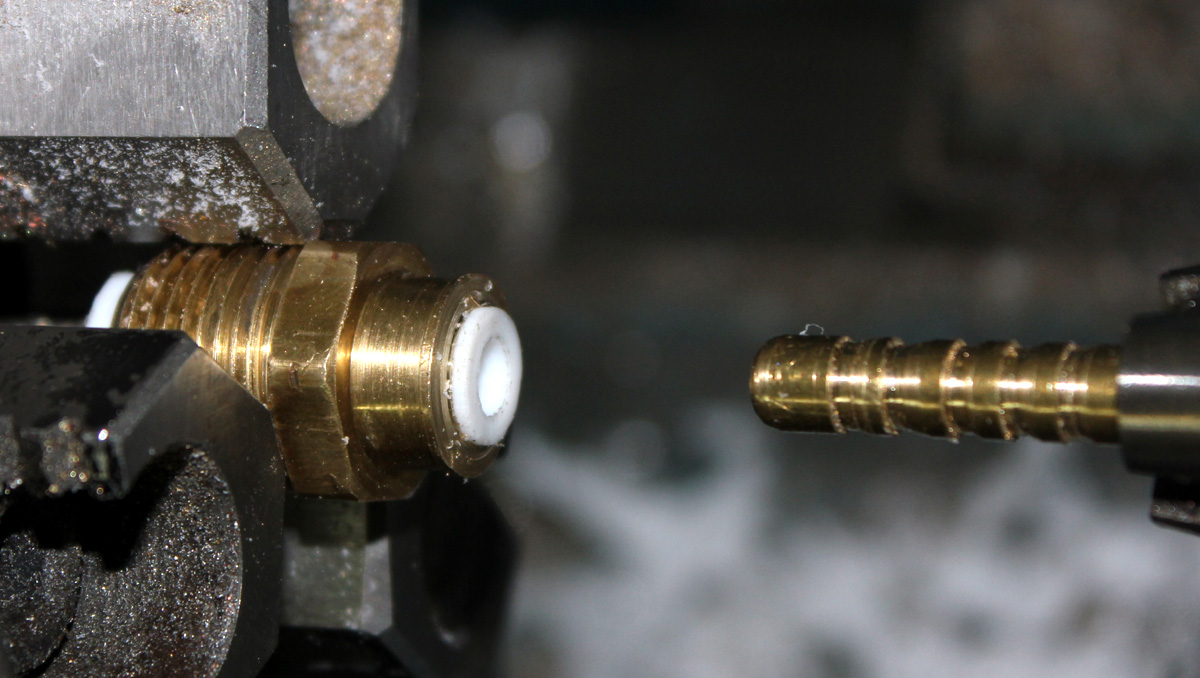

I machined the following parts. I make a barbed rod for

my probe tip. I put a taper on the ribs that allow it to push into a hole and

lock, just like a normal barb is machined. This is the tip that sticks down into

the water to probe the flowing water:

I machined a Teflon rod into an insert that had interference fit to the inner

probe and the outer threaded body:

The result has a large lip for the water side and a step to match the inside

of the threaded fitting. This makes the water push it in tighter, no matter what

the pressure. This Teflon insert presses with an interference fit down into the

cut off and drilled hose barb fitting:

The probe ribs were machined into a barb angle. The severe interference fit, in

combination with the lip and barb steps, make a very tight pressure seal. The .250 inch

OD brass center probe insert has .075″ deep barb ribs that allow the insert to

be pressed in, but seal and lock it in place against pressure. Additional sealer

was not

necessary. It was leak and blow out tight even at a 100 psi test:

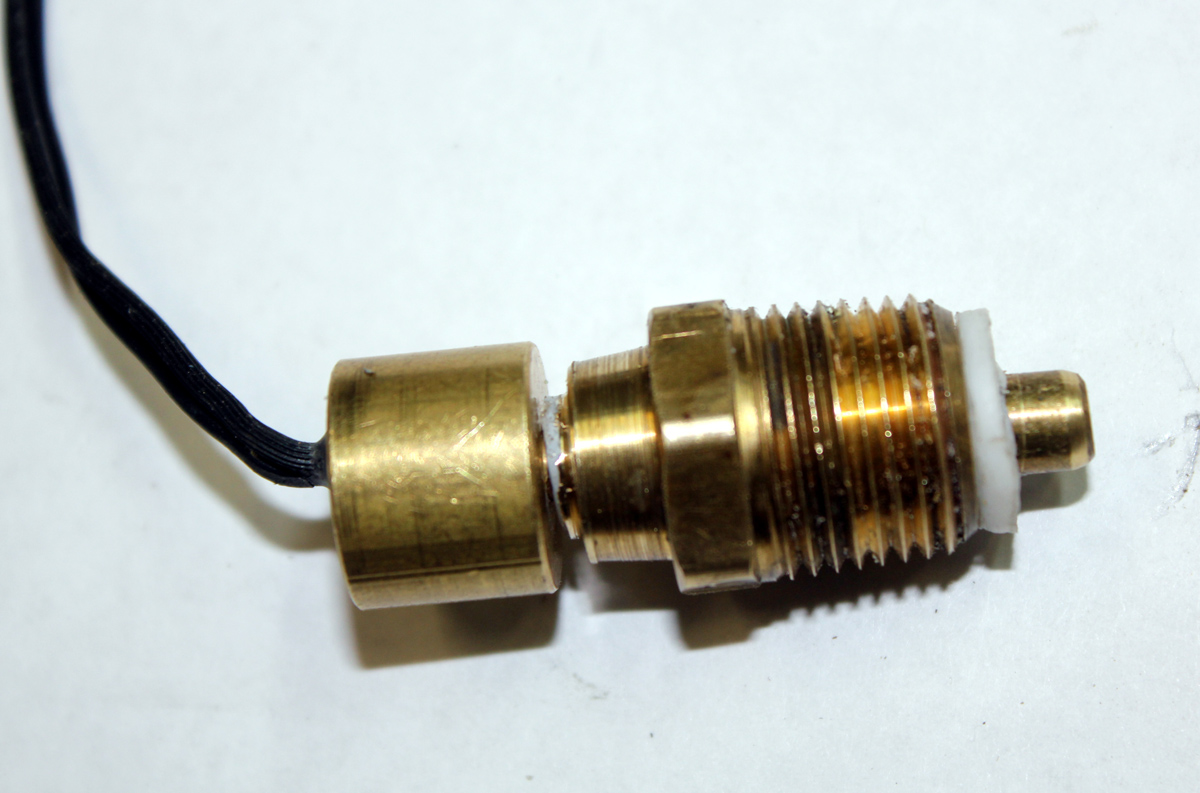

The final result look like this. The Derale sensor

screws into the blind 6-32 tapped hole on the right. The tip sticks down into

the water. The Teflon, which has very low thermal conductivity, prevents

manifold temperature from skewing water temperature readings:

The 6-32 hole in the insert allows the Derale thermistor

assembly to be attached like this:

As an added feature, I run an electrical connection from the sensor housing

back to my car electronics. I did this by adding a lug between the Derale sensor

and the threaded rod that sticks into the water. This lug lets me sense the

small current that flows when the tip has contact with the coolant. When my

coolant gets low, I get a warning light.