|

Related articles at

Balun Test

contains model of “perfect” dipole currents.

Sleeve Balun

shows how a sleeve adds impedance, useful for VHF and higher baluns

Receiving Common Mode

Noise shows how lack of a balun can contribute to system noise (it applies

to transmitting antennas as well)

Longwires, Verticals,

and Baluns shows how unbalanced antennas can have similar problems

Transmitting baluns

on testing transmitting baluns

Occasionally errors are made regarding core selection. This especially

includes baluns, where on occasion some very strange ideas surface. One rather

odd but somewhat popular idea is that adding a mixture of core types will allow

both high power operation and high choking impedance in baluns by slowly

reducing current through a balun. Other misleading claims are that extreme

values of core ui, such as values in the 10,000 or higher range, are necessary

on 1.8 MHz and higher. Other ideas tend support use of excessively low

permeability cores for the same application.

When I recommend a core, the material selection is always based on actual measurements

with proper test equipment on a bench as well as in the actual end-application.

Core Material

I mainly use 73 material for receiving applications in LOW POWER

applications between

.1 and 30 MHz. 73 and similar core materials generally minimize the turns count

required without inducing excessive loss. One of the best indicators of correct core

selection is looking at the turns required. You’ll notice most of the

transformers I use have only one or two turns for every 100 ohms of impedance.

My 75 to 450 ohm Beverage transformers, for example, only require two-turn

primary and 5-turn secondary windings. A low “turns count” is a good indicator the correct core

size and core material is being used.

For high power applications at HF it is often necessary to use lower permeability cores.

There are two reasons for this:

- Lower permeability cores generally are available with higher curie

temperatures. They operate at high temperatures without losing their

magnetic properties.

- Lower permeability cores have higher Q (lower loss tangent) at a given

frequency. This means a larger part of the impedance is associated with

lossless reactance rather dissipative

resistance. They turn a smaller percentage of power into heat, and that is

very important at high power levels.

Permeability changes with frequency. As frequency is increased from

zero eventually core impedance peaks. Above the frequency where impedance peaks the impedance of the core (and the

effective

permeability) actually decreases.

A downward slope in permeability with increasing frequency is useful for controlling

impedance in broadband

transformers, but we should be careful to avoid excessive slope. Excessive

initial permeability can easily move the operating area too far out

on the downward slope of impedance.

A transformer or inductor operating on the downward slope of a high ui core requires

extra turns to maintain critical impedance and often requires more turns than a lower ui

core. The upper frequency limit will decrease, and

this may reduce useful bandwidth in the desired frequency range.

Using excessive initial permeability means winding becomes more tedious (it

takes more turns). The wire has to be smaller and more fragile to fit a given core

window. Temperature stability is often reduced while losses increase over an optimum

core material selection. In addition, stray capacitance increases

needlessly, reducing bandwidth and increasing unwanted stray coupling.

Do NOT pick cores solely by considering initial mu, since that value is taken at dc.

You should consider characteristics measured at the

operating frequency!

Always remember this general guideline. Les wire length (as long

as winding impedance is sufficient) results in better transformer bandwidth. The best designs place maximum conductor length INSIDE the

magnetic core window, and

minimum conductor length OUTSIDE the core window.

Heating

At higher power levels, it is necessary to

move to lower loss tangent and higher curie temperature materials like 65,

61, or (in extreme cases) 43 materials. Even a fraction of a dB loss produces significant heating in small cores

when power level is in the kilowatt range. The loss DIFFERENCE in

non-resonant applications between lower and high ui ferrite cores isn’t significantly different, but

heating can be much

less!

We often assume heat means a core is very lossy or is “saturating”, but this

often isn’t true. We must consider the power level, duty cycle, and

ability of the core to dissipate heat and look at the full picture.

Very small cores, such as small thin .5

inch diameter cores used on bead-type choke baluns, can only dissipate a

fraction of a watt in open air. It sometimes helps to put temperature in

perspective by visualizing how hot a 60-watt light bulb runs in normal

operation. When we consider the core’s size, it usually has significantly less

surface area than the bulb. The core also has poor thermal conductivity, and is often stuffed in a container

preventing any type of air circulation.

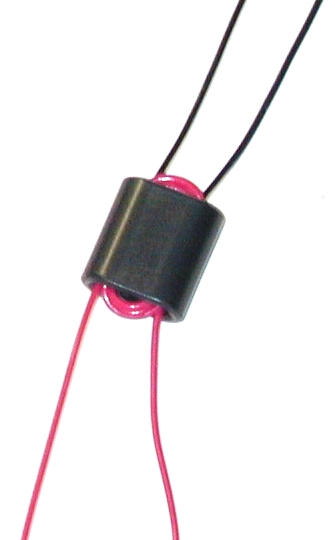

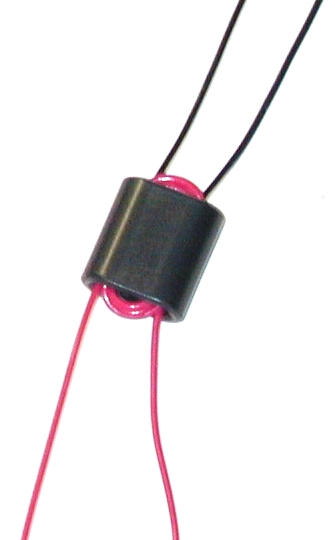

Consider the construction of a typical bead balun, enclosed in PVC and heat

shrink tubing. As little as 20 watts dissipated out of 1500 watts can produce

damaging heat in tiny beads enclosed in a PVC tube. 20 watts out of 1500 is less than 0.1dB

loss, yet it overheats the core!

The problem is almost always a

heating problem, and not a core-loss problem. It is almost never core saturation, unless

the core is subjected to very low average

power and very high peak power levels. It is best that we worry about heat and

the number of turns we use, not actual power loss, when selecting a core.

Core Style

Soft-iron cores (soft magnetically) increase inductance because they increase

flux density near a conductor for a given current. With only a small

amount of flux “concentration”, there can not be a large increase in

inductance or impedance. We need a significant increase in flux to have a

significant increase in impedance.

The area outside the core window does NOT have a closed magnetic path

surrounding the conductor. The

presence of the core has a minimal effect on impedance of any conductor area outside the core window.

Most of the flux from external wires is in air, rather the core. With only a portion of the flux

surrounding the outer conductors cutting the outer layers of the core, the useful

impedance contribution of wire outside the core window to system impedance is minimal. Conductor

length outside the core window mostly adds unwanted stray reactance and leakage

flux. If we MINIMIZE the wire length exposed outside the core, and we

generally have a more effective inductor, choke, or transformer.

This effect can be easily conformed in a simple experiment using an

antenna analyzer. Connect a short wire across the output of an analyzer, and

measure the impedance. Lay a core against the wire, and observe the very small

impedance increase. Now pass the same wire through the core center, and observe

the large impedance change. This illustrates why the winding’s wire length on

the outside of the core is wasted, mostly contributing to undesired

effects.

Core Dimensions

The area inside the winding-window of a soft-iron (soft magnetically, not physically) core is cut

by all of the flux lines, and this area has a very large effect on

impedance. The core concentrates the

magnetic flux surrounding a current-carrying conductor into a very small area,

and the thickness of the core moving away from the area of the conductor very

rapidly has less effect.

- The additional impedance caused by placing a core over a conductor or

conductors is almost entirely proportional to the core’s

internal length (window depth) paralleling and surrounding the conductor

or conductors.

- The core diameter or

radial thickness only has a small effect on impedance.

Doubling the core area parallel with a conductor roughly

doubles winding impedance. The same is NOT true for an increase in core wall thickness,

core thickness barely affects impedance.

I prefer binocular cores for most low-power applications and side-by-side

stacks of cores (making a large “binocular core”) for high power

broad-band applications. This type of core arrangement

almost always minimizes the amount of conductor hanging “outside the

window”. With very little conductor hanging “outside” the core window,

there is less “needless” wire adding undesired stray capacitance and series

resistance. For a given core material and impedance, conductor length can often be reduced to

about one-third of a similar impedance choke (or transformer) using a conventional

single-hole core or single stack!

Low Power Measurements

Phase Inversion and Choke Baluns

Some of my receiving system designs use phase-inversion transformers.

Phase-inversion transformers are identical to (and interchangeable with) choke

baluns or line-isolation transformers. For HF receiving applications, 73-material binocular cores

are wound with six passes of #26 twisted-pair enameled

wire. I use Fair Rite Products 2873000202 cores (about 1/2 inch square and 1/3

inch thick 73 material).

Here are measurements of a sample inversion transformer at 2.5MHz using

accurate (and fairly new) commercial equipment:

| Load Value (ohms) |

Loss (-dB) |

Phase Error (degrees deviation from 180) |

| 100 |

~ 0 |

<1 |

| 33 |

~ 0 |

-1.2 |

| 10 |

0.2 |

-2 |

This shows inverting transformer construction is good, since even a 10-ohm impedance

load works well!

Beverage Matching Transformer

Sometimes I use designs for a long time, and forget how I decided they were

OK. I recently received an e-mail questioning the number of turns in my Beverage

transformer design, so it seemed like a good time to re-confirm the design.

I retested a 2:5 turn ratio transformer using a single FairRite Products

2873000202 core (about 1/2 inch square and 1/3 inch thick 73 material) two different ways on a generator/

network analyzer/vector impedance test set.

Total loss of two back-to-back transformers was .84dB at 1 MHz increasing, not

decreasing, linearly to .98dB at 30MHz. The actual transformer loss would be

.42dB at 1MHz increasing to .49dB at 30MHz.

Doubling turns increased the attenuation slope. While 1MHz loss decreased to

.69dB per pair, 30MHz loss increased to 1.21dB. This was for a PAIR of

transformers connected in series to make a 1:1 transformer. This of course

removes mismatch losses, so it is twice the real transformer loss. Actual loss

would be .35dB @1MHz increasing to .61dB at 30MHz.

Measuring a second way, I terminated the transformer in 470 ohms. Loss

measured .65dB at 1MHz when mismatch loss was included. Since receivers have

wide ranges of input impedance, any mismatch error might help OR hurt actual

system loss. Factoring out mismatch loss the second measurement indicated about

.53dB 1MHz loss with the original 2-to-5 turn transformer and .43dB with twice

the turns.

Every measurement has tolerances, and the two different methods do provide

different losses because measurement errors affect results differently. Still,

it is safe to say doubling turns has a negligible effect on 1MHz loss (which is

around .45dB).

|