|

Transmission Angles

Centering the transmission is reported to be necessary. This

is an analysis of how centering affects gear alignment inside the transmission.

First, let’s look at what Tremec says. As of March 3, 2015,

this is all they say:

Q: How do I index the bellhousing, and why is it important?

A: To say you have an improperly indexed bellhousing is also to say that

your transmission is improperly aligned with the engine in front of it. What

this means is that the input shaft is not sitting true into the pilot

bearing, which can cause a long list of transmission-related problems; as

small as hard shifting or as big as total product failure. We are currently

working on putting together our own online installation guide to address

these issues. However in the meantime, there are several articles online

that explain the principles of driveline angles and how to properly set

them. Here is a link to get you started:

http://www.carcraft.com/howto/91758/index.html

The link isn’t even a good one. It is for rear ends.

I found this link:

http://www.hotrod.com/how-to/transmission-drivetrain/ctrp-0404-bellhousing-alignment/

In it, they say:

As you are measuring a circle, remember misalignment is one half of the

indicator reading. It’s best to always use the same location spots as you go

through measuring and fitting. The Lakewood personnel who showed us how to

do it marked the 12:00 and 6:00 locations with their readings. If the

reading is within tolerance of 0.005 after checking twice, you’re ready to

go racing.

Here is an article that appears to be loaded with

“dramatic bologna”.

http://camaros.org/bellhousings.shtml

In that article, they claim:

As an example of the damage that can result from misalignment, the

photo below shows a seized throw-out bearing stuck on the transmission

input shaft bearing retainer. In this case, the bellhousing to block

alignment was out of tolerance by 0.014 inch. This misalignment created

excessive stress on the pilot tip of the input shaft, which eventually

fatigued, broke off, and allowed the transmission input shaft to wobble

extensively around in the crankshaft. This resulted in tremendous heat

sufficient to cause the throw-out bearing to weld itself to the bearing

retainer. When this happens the vehicle is not driveable at all. Note

the broken ear on throw-out bearing from trying to remove the

transmission.

|

I’ve seen similar misdiagnosis is electronics, where

components fail. It is common when something breaks, and someone with good

intentions looks for anything at all wrong to blame. A misdiagnosis like this is

actually very common. (As a manufactured product engineer I have to look at and

analyze equipment failures. Around half of my work deals with solving OEM

reliability or field failure problems.)

The truth is, we really can’t know why the input shaft

tip broke. What we do know is the angle misalignment was around, and probably

less than, 0.15 degrees error.

Let’s look at what alignment means.

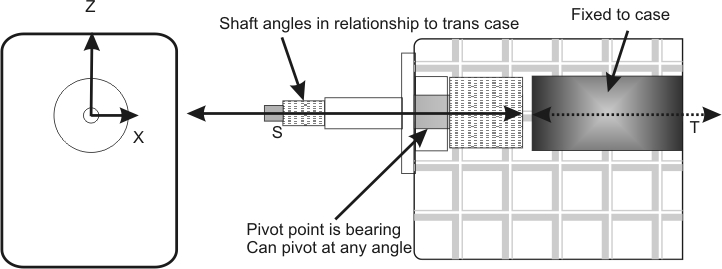

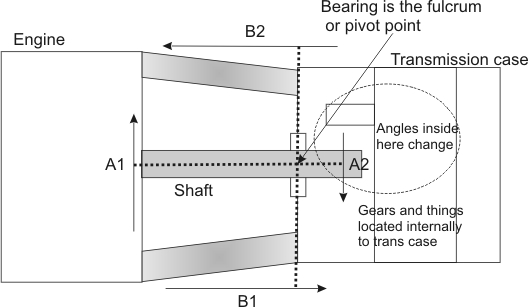

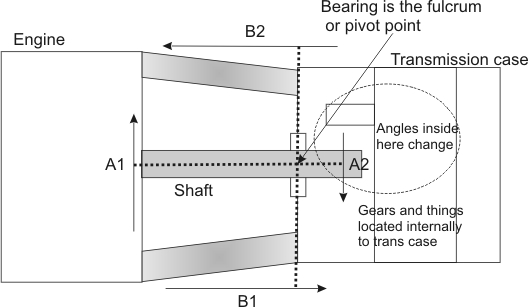

A rough drawing of a typical transmission follows:

There is an input shaft with dimension A that connects to a

gear inside the transmission. That gear has a large helical gear that drives a

cluster gear that sits next to the input shaft, and the input shaft has small

radial tooth set on the end that drives a straight-through slider connection for

direct drive.

The input shaft floats inside a sleeve. The input shaft is

supported by a bushing in the crankshaft end center, and a second support by a

roller bearing race at the transmission front. The crank center pilot bushing or

bearing and the transmission input shaft bearing (which allows some small

tilting angle) are ONLY supports for the input shaft. The alignment of the crank

bushing and the transmission input bearing center, along with the flatness

of the transmission case to the crankshaft centerline, set the

angle of the input shaft to the cluster gear (cluster gear tooth mesh) and the

input shaft to main shaft alignment.

The AMOUNT of angle change and the physical movement,

as a percentage of external misalignment, depends on the distance from the pilot

bearing to the transmission input shaft bearing, and the distance from that

bearing to the mating gear or slider.

I’m not going to get into the claims of great damage by small

alignment errors, but rather focus on how this works. The reason for this focus

is to let YOU decide if everyone measures things that actually mean

anything, or that guarantee alignment.

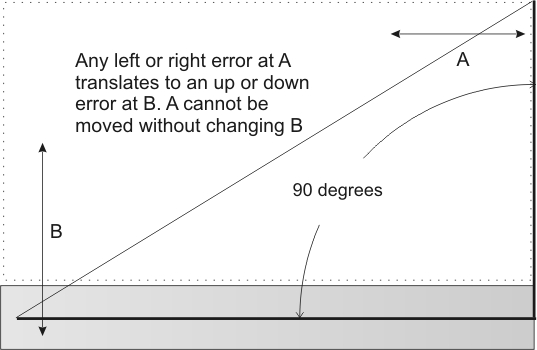

Alignment is important three ways. The Z and X axis (normally

checked), and the crankshaft centerline to transmission case front angle (which

should be exactly 90 degrees) that is almost never even considered

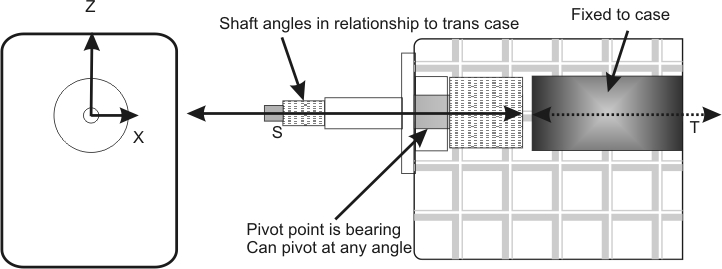

1.) The transmission input bearing is a fulcrum point for

alignment issues for deflection in inches

2.) The transmission case face to crank centerline also

directly affects alignment. The alignment degrees should be exactly 90, and the

angle error is NOT stepped up or down by shaft lengths

3.) The crank pilot centerline to transmission input bearing

center determines distance alignment errors through a lever action, like a

teeter totter! Any error is stepped down by the ratio of shaft length outside

the input bearing to contact point of the input shaft inside the transmission

4.) I will assume the transmission is constructed perfectly

inside, without any alignment error internally and it holds gears and the

transmission holds internal shafts perfectly rigid in alignment (good luck on

this with hundreds or, depending on the gear and the engine, many thousands of

lb/ft torque distorting things!)

Crankshaft to bellhousing transmission center location errors

Any centering error of the shaft or transmission, measured at

the bell, is translated by the ratio of shaft outside the transmission bearing

center (B) to length inside the transmission at the contact point to F.

If we look all the way at the end of F, it might be dimension C. In

this example the very worse case alignment would be C/B * error = actual

internal error

Let’s say we have .005 inch error outside in transmission

centering, and everything else is perfect. The internal distance error would be

.005* (C/B) = .005 * (3.7/6.8) = .005*.544 = .00273 inches.

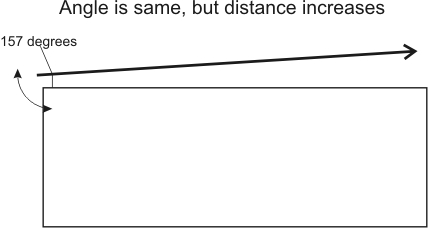

The degree error would be the same. If we had a .05 degree

error outside, it would be a .05 degree error inside. Angular error is not

changed or modified by lever action.

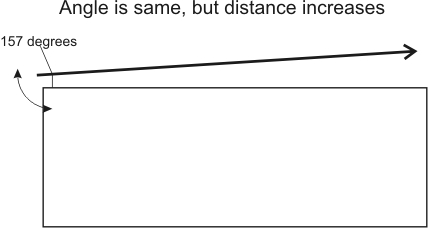

This works like a teeter-totter, or a triangle or

parallelogram geometrically. With a fixed degree error, a long physical distance

between points means far

more than a small distance angle error. The distance error can also be

multiplied or divided by lever ratios to the pivot point or fulcrum. Think about

it this way; let’s say we are installing a long fence. We measure two points 120

inches apart, and make a 1 inch mistake. At 240 inches, the error is the same

number of degrees but becomes 2 inches.

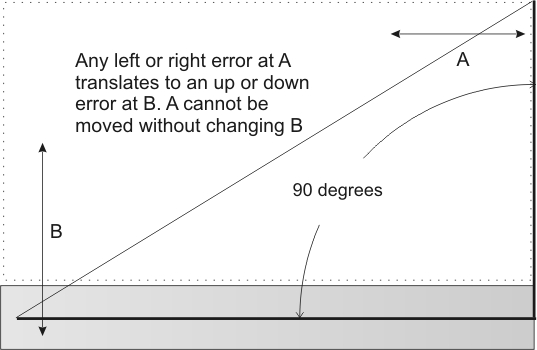

Looking at the face, shaft, and bellhousing we find:

This is why the transmission face distance error to the

crankshaft center line (through the bellhousing) means far more than the

centering of the transmission in the bellhousing hole (or input shaft centering

to the crank center). That angle should be 90 degrees, but is so difficult to

measure accurately I doubt anyone does it. Measurement error would probably

exceed machining errors because almost no one can measure

small right angle errors accurately. I have machine equipment, and cannot

measure .05 degree errors. If dust gets on the surfaces, or a hair gets in the

way, the error can be .002 inches or 0.2 degrees or more.

Angles and Distance

Putting size into perspective, the average thickness of a

human hair is 0.004 inches.

Let’s say the input shaft tip is 6.8 inches forward of the

input bearing center, and we measure a bellhousing hole error of .005 inches

down. This crank centerline error shifts the transmission bearing down .005

inches to the crank, which is the same as lifting the input shaft nose by .005.

This moves the input shaft gear down .005 * C/B or .00272 inches at the

furthest point of the input shaft. If the input gear was 1.5 inches

forward from the end where the slider teeth are, the start of the gear would

shift down .001618 inches, or less than half a hair.

Now let’s say the locating hole center is perfect, and the

transmission top is .005 inches back from the shaft centerline. This .005 inch error

is equivalent to moving the input shaft tip up .005*B/D = .01236 inches. This

.005 inch backward move in relation to shaft centerline position is .01236/.005

= 2.47 times the error caused by hole centering on the crank. This means if the

paint on a perfectly machined bellhousing is .005 inches thicker at the

transmission top edge, it is like having the hole center .01236 inches off.

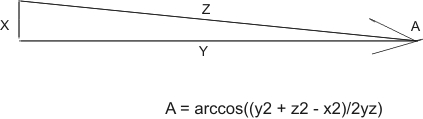

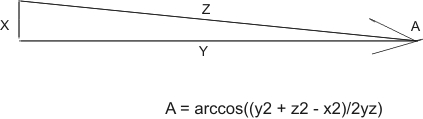

Angle A is the arccos (or also written cos-1) of (y squared + z squared – x

squared ) over 2 times y times Z For .005 inches deviation measured over 6

inches, the angle is: cos-1 (6^2+6^2-.005^2)/2*Z*Y = 71.999975/72 = cos-1 of

0.999999653 = .047746469 degrees.

If we offset the bearing centerline on a six inch long shaft by .005 inches,

the degree error is less than .05 degrees. A .005 inch error measured over 6

inches spacing causes a degree alignment error of a little less than 0.05

degrees.

Now you see why I am starting to have a problem with, or at

least be very skeptical about, the idea that measuring hole center is

meaningful.

Since we cannot measure what matters, we measure

something we think (and everyone says) solves the problem. We make something to

be a problem, we

ignore what is probably a much larger problem source, and we fix the problem we

invented.

I’ve been installing stick shift transmissions for about 40

years or more, and never measured the locating hole center one time.

|